HINO TEAM SUGAWARA Reports on its 5th Straight Class Championship at Dakar Rally 2014

Mar 19, 2014

Huge applause for a team that continues to take on the challenges of "the world's most grueling rally"

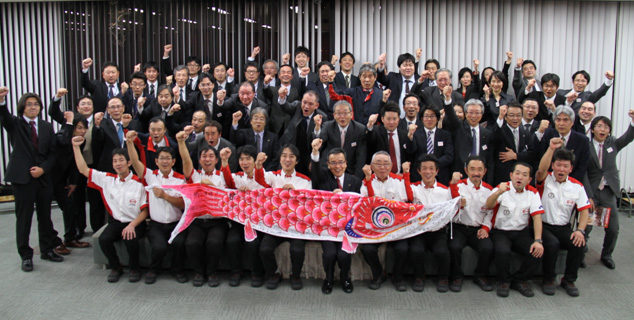

March 12th - HINO TEAM SUGAWARA, which won its fifth straight championship in the Under 10-litre Class in the Trucks category, and celebrates 23 straight finishes since the team first started participating in the race, held a publicity event at Hino Motors' head office, sharing their jubilation with the 200 people present.

Present at the event were Yoshimasa Sugawara, team director and driver of Car 1; Teruhito Sugawara, driver of Car 2; navigators Katsumi Hamura and Hiroyuki Sugiura; mechanic leader Seiichi Suzuki; mechanic sub-leader TakeshiSuenaga (Vehicle Planning & Production Engineering Division, Hino Motors); mechanics Hiroaki Tamura (Higashi-Hokkaido Hino Motors), Norishiro Senuma (Yokohama Hino Motors) and Tadahiko Fuke (Shiga Hino Motors); engineer Katsuyuki Nagoshi (Engine Engineering Division, Hino Motors), and Hino Motors President Yasuhiko Ichihashi.

Mr. Ichihashi, who was first to take the podium, praised the team for its outstanding performance and expressed his gratitude for the generous support offeredby the many sponsor companies. Teruhito Sugawara then gave the audience a description of the characteristics of the 2014 race course and how HINO TEAM SUGAWARAcompeted throughout this extreme race. He was followed by mechanic sub-leader Mr. Suenaga, who shared his and the team's experiences during the race. Last at the podium was Yoshimasa Sugawara, the "Iron man of Dakar," who at age 72 continues to compete in "the world's most grueling rally" and finished this year's race in fine form. He's already gearing up for next year's race.

When highlight footage* of the team's heated struggles during the 13-day race was shown, the audience of about 200 - including members of the board and employees of Hino Motors and our sponsor companies - responded with non-stop applause as they watched dynamic scenes of HINO500 Series trucks kicking up sand and dust as they crossed the dunes.

* View the highlight video on the Hino Motors website

https://www.hino-global.com/corp/dakar/gallery/video1.html

Yasuhiko Ichihashi, President of Hino Motors

"We are committed to bringing the technological capabilities and teamwork that we develop in this rally to our vehicle production and services."

"I am very happy to announce the results of HINO TEAM SUGAWARA's performance in this race today. In this year's Dakar Rally, Teruhito Sugawara was able to win his fifth straight championship in the Under 10-litre Class, with his father Yoshimasa coming in second place to achieve a one-two finish in the class for the team. For Hino, we were able to extend our record of straight finishes to 23 since we first started participating in this race in 1991. I would like to extend my heartfelt feelings of respect and gratitude to our sponsors, as this would not have been possible without your efforts and support,as well as the cooperation and support offered by all of our employees. Thank you very much."

"Our mission at Hino is to make the world a better place to live by helping people and goods get where they need to go - safely, economically and with environmental responsibility - while focusing on sustainable development. Our participation in the Dakar Rally, which is known as 'the world's most grueling rally,' is an important part of our efforts to improve our technological capabilities with regards to vehicle production and strengthen our unity as 'team Hino' as we work to achieve our goal. Our intent is to give something back to those who have extended their support to Hino by bringing the technological capabilities and teamwork that we develop in the Dakar Rally to our vehicle production and services to better serve our customers around the world."

Teruhito Sugawara, Driver of Car 2

"My goal is to show everyone how fast the HINO500 Series trucks have become."

"This was the sixth year since the Dakar Rally relocated to South America. Just a few days into the race, many of the teams were commenting that this year's courses were really tough. Not only were they long, but a characteristic of this year's courses was that they were very difficult. Consequently, the overall finish rate dropped to less than half - 48% this year compared to 67% last year. Given this reality, we're very happy to have been able to achieve one of our goals in finishing one-two in the Under 10-litre Class and winning our fifth straight championship. In terms of overall rankings, Car 2, which I drove, came in 12th place, seven positions up from last year's 19th place."

"The first part of the race featured high speed courses, and the dust was brutal. Everyone was racing in the same direction in the same area, so we were essentially stepping on the gas pedal blind with all the dust obscuring our view. This increases the risk of falling into potholes, but if we slow down we risk being overtaken. The key to racing in this situation is to know how to drive the vehicle fast even under such conditions.

"Another distinct difference from African courses is that these courses take us through very high altitudes in the Andes Mountains. Some SSs (special stages) were set at 3,800 meters, which is higher than Mount Fuji, and some liaison routes took us even higher, up to 4,700 meters. Hill climbing taxes the engine and descending is hard on the brakes, so it's a very nerve-wracking situation for us, and tough on the trucks as well. There are also narrow roads along cliffs where it can be quite difficult to pick up time, but the real risk is that if you fall, you fall to the bottom. The cliffs are actually about 100meters high, so these regions are quite dangerous. There are also areas where we would drive on long stretches of solid rock, and although I've never been to the moon, that's the way it feels." (Laughter.)

"In the deserts, we came across dunes that were as big as the ones in Africa, which we climbed over one after another. Having greater engine output is a definite advantage, but dunes also require finesse. You have to have experience to be able to drive through these regions while other drivers are stuck in the sand, and this is one of our areas of strength. We'll be making engine power upgrades from here on, so we're looking forward to improving our time in dune areas as well.

"In this year's race the A09C engine gave our trucks more acceleration, and we'll be fine-tuning the suspension and making other modifications to create a truck we think will be able to race neck-and-neck with our oversized rivals. While we do see ourselves winning our sixth straight championship in the Under 10-litre Class, our dream formany years has been to have the Hino emblem show up in a high position in the overall rankings. My goal is to show everyone how fast the HINO500 Series trucks have become as we catch up with and eventually overtake our rivals. I'm sure you'll enjoy our races."

TakeshiSuenaga, Mechanic Sub-leader

"Everyone's rooting for us. We can't let them down! "

"As mechanics, we arrive at the camp site, which the organizers call a 'bivouac,' earlier than the race trucks and prepare for their arrival. We sleep in the support cars, but every time our satellite phone rings we just jump up with the thought, 'Is there some kind of trouble with the racing trucks?' Fortunately, we didn't encounter any major problems so we should've just gone back to sleep, but it's tough to get back to sleep in those situations.

"While we didn't encounter any major problems, our day-to-day work was quite intense. Every day we first listened to what the crew told us, inspected the trucks, decided on our servicing procedures for the day and shared responsibilities to complete the servicing work prior to departure. After we saw the race trucks off in the morning we headed out to the next bivouac. This was our routine day after day. We were all pumped up, thinking,'OK, we're going to service these trucks, and we're going to get it done by morning!' But toward the end of the race we found ourselves having to fight the fatigue we'd all accumulated, as well as sleepiness and sometimes the cold, which could thenlead to careless mistakes. I made sure to getthe mechanics together and have them rest when I felt things were getting to a point where we could be making major mistakes or causing accidents if we didn't get some rest. During our rest time we would read the many messages of support on the website, and these messages really gave us mental support. The spirit was that everyone was rooting for us, and we couldn't let them down. This gave us greater focus in our work and the strength to perform even better.

"That was how those 13 days zipped by for us. In the end, both HINO500 Series trucks and the entire team were able to make it to the goal. The ceremony venue was overtaken with a festive atmosphere. As we were on the roofs of the trucks' cabs and waving to the crowd, I felt that all of the extreme hardship we'd gone through had transformed into fond memories. At the same time, my heart was filled with a feeling of gratitude to the mechanics and crew with whom I'd fought this battle, as well as the support staff, people who took care of us in Argentina and Chile, and those who were cheering us on from Japan.

"Having now taken part in the Dakar Rally, I was surprised to see that it involved so many people. This made me realize that our HINO500 Series trucks were only able to race thanks to the Hino group company staffand suppliers working as a tight-knit team?and we were able to take part in that race. I would like to share my experience in this race with as many people as possible at my workplace so I can make the best of this experience and do my part in giving something back to everyone who supported this effort. I would like to thank you all from the bottom of my heart for your cooperation and support."

Yoshimasa Sugawara, Team Director and Driver of Car 1

"We're looking to make the trucks much, much faster next year."

"I'm very grateful that this year we again received support from many, many people. While we haven't made any specific decision regarding the next race, we've had numerous meetings with the working group since we returned to Japan and decided on a rough picture of what we'll be doing.

"We used the 9-litre A09C engine this year, and it performed extremely well. We were plagued by overheating last year, but we had no such problems this year. Making our engines bigger was one thing, but the trucks' legs, or suspension, had a hard time keeping up with it. A few days into the race we noticed how the engine's driving force wasn't being transmitted to the ground surface and how the chassis bottom would occasionally hit the ground. We were expecting something like this and brought multi-leafed springs with us,so we replaced our springs during the rally. You'll have to leave it to us to rob our mechanics of their sleep time!" (Laughter.) Replacing the assembly is really a lot of work, and we appreciate how our mechanics worked through the night regularly from there on. All 13 of those days were essentially test runs for the truck, and in the end we were able to bring it up to 80% of what I had envisioned.

For our next race, I'm hoping we can tune the engine from the current 600 horsepower to around 700 horsepower." (Laughter.) "We're also coming up with a lot of ideas for our suspension, so we're looking to make the trucks much, much faster next year.

"On a related note, we took two daring steps this year. The first was that we worked to develop better aerodynamics with Takuya Yura at Moon Craft. Mr. Yura is the top authority in aerodynamics in Japan, and he was very eager to take part because, in his own words, "I've never done trucks." We tested on a one-tenth scale model and found that we could improve aerodynamics by about 10 percent by adding a visor to the front part of the cabin. Upon actually driving the trucks in the rally, we felt that this had a huge effect. We also made modifications to direct the air to the intercooler right behind the visor to improve cooling performance.

"The second step was that Hino engineers visited Yoshimura Japan, a company known for tuning motorcycles, to work together and ask for their input. When I was younger, truck developers would dismiss you out of hand saying things like, 'Motorcycles and diesel engines on trucks are completely different beasts!' But the younger generation today have no hang-ups about these old lines in the sand, and work together with a feeling of mutual respect. I think this is a very good thing and it was a great experience for me too.

"We'll be working hard to win our sixth straight class championship next year, so I would like to thank you all in advance."

You can find the Daily Race Report, where we reported on race details everyday, on the Hino Motors website.

https://www.hino-global.com/corp/dakar/latest_news/2014/